Manufacturing

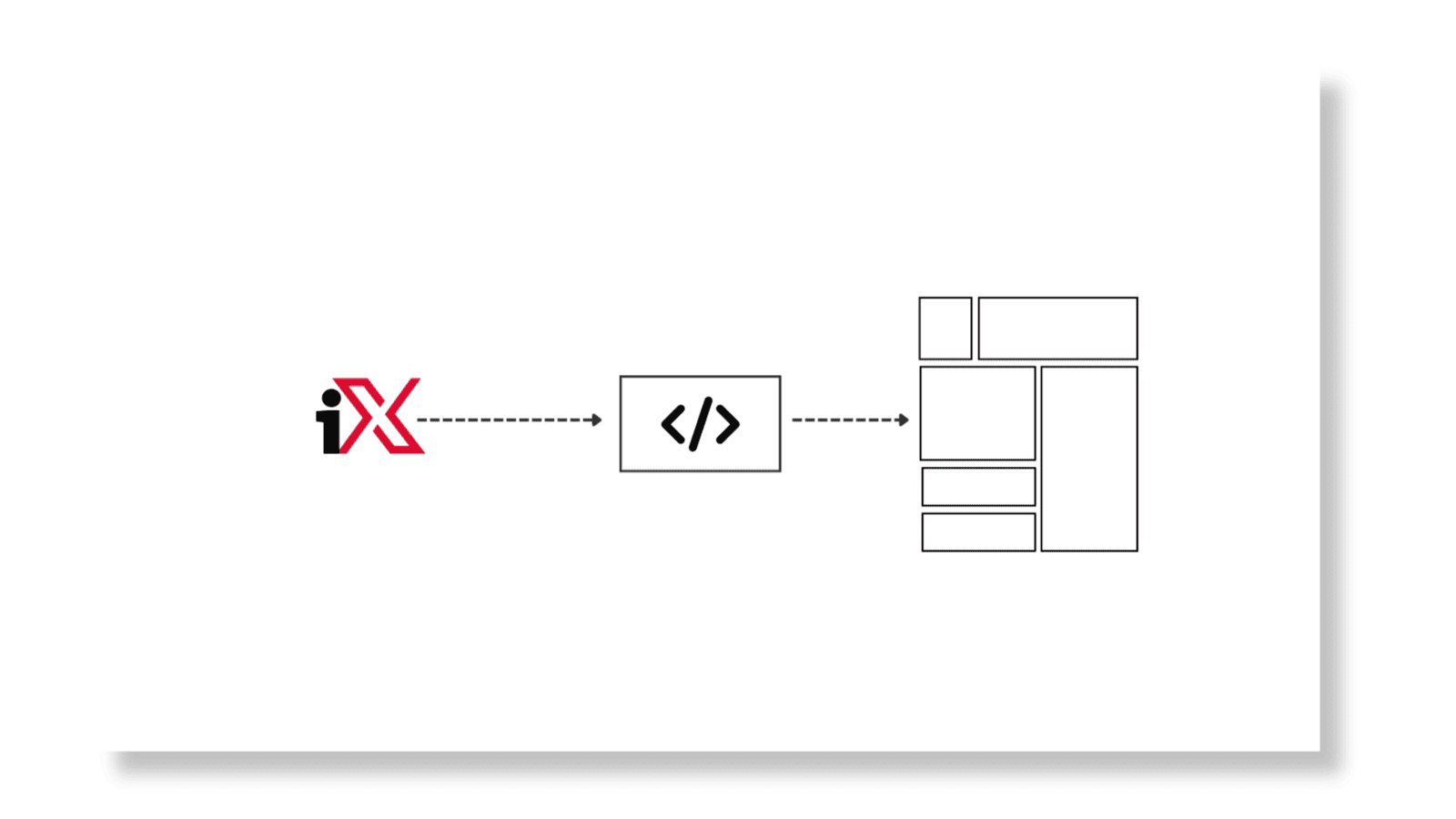

From design or online store straight to production: iX CAM automatically creates CNC programs that are compatible with all leading machine manufacturers, ranging from individual machines to workshop cells and interconnected production facilities. It integrates effortlessly with internal production processes, ensuring that NC data generation is tailored to the unique production workflow. This approach ensures the highest standards of safety and quality throughout the production process.

Advantages

- One-click data export for streamlined processing

- Modify NC programs without altering the master data

- Flexible access to order and production documents from the cloud

- Specialized machining strategies for solid wood processing and edge banding on CNC, 5-axis, and nesting machines

- Generate production lists and NC data directly from iX CAM

- Unique part identification with barcode labels for easy tracking

- Option to track time for each machining operation

- Accurate calculation of machining times for optimized production planning

iX CAM

From planning or design directly to the machine: iX CAM automatically generates CNC programs from finished design drawings or the online store for all major machine manufacturers. Whether for an individual CNC machine, a workshop cell, or a networked production plant, iX CAM ensures seamless integration. In addition, in-house production processes can be easily mapped and CNC data generation is optimized for the specific production flow—delivering efficiency, reliability and cost-effectiveness.

Highlights

- Precise machining data for optimal production accuracy

- Directly retrieves geometry and machining information from iX CAD

- Flexibility to implement diverse workflows

- Barcode assigned to each program ensures smooth and reliable production

- Eliminates human intervention, reducing errors and saving time

- Customer configuration instead of custom development

- Enables sandwich machining support

- Ensures safe and efficient production with controlled parameters and filters such as grain direction and part size

Features

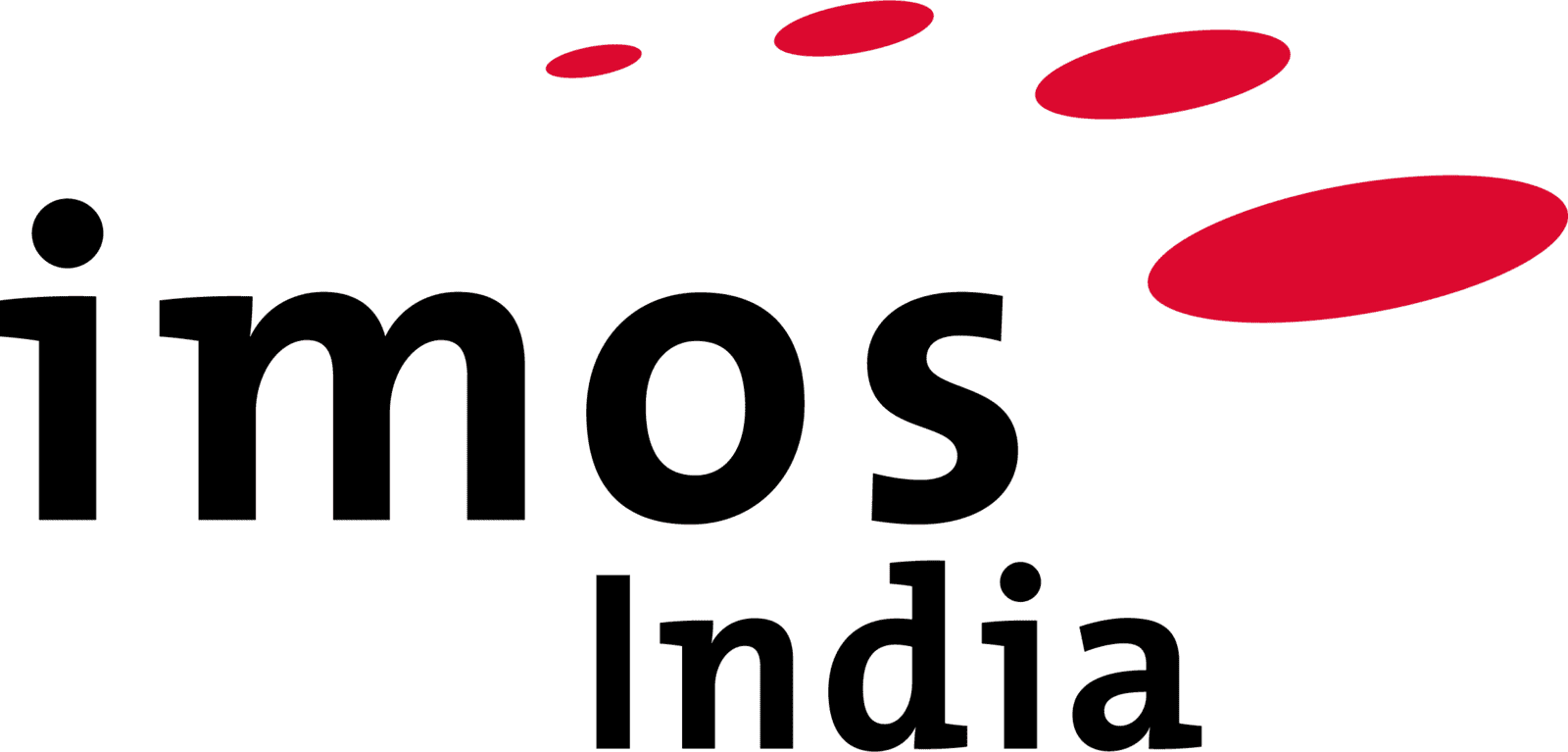

Streamline Production with Workflow-Driven Data Flow

- Seamless integration of workflows for efficient production management.

- iX CAD Integration.

- Programs generated based on component dimensions.

- Enhanced Production Workflow.

- Processing Steps Management.

- Determine the production path for each component.

- Ensure optimized routing and processing.

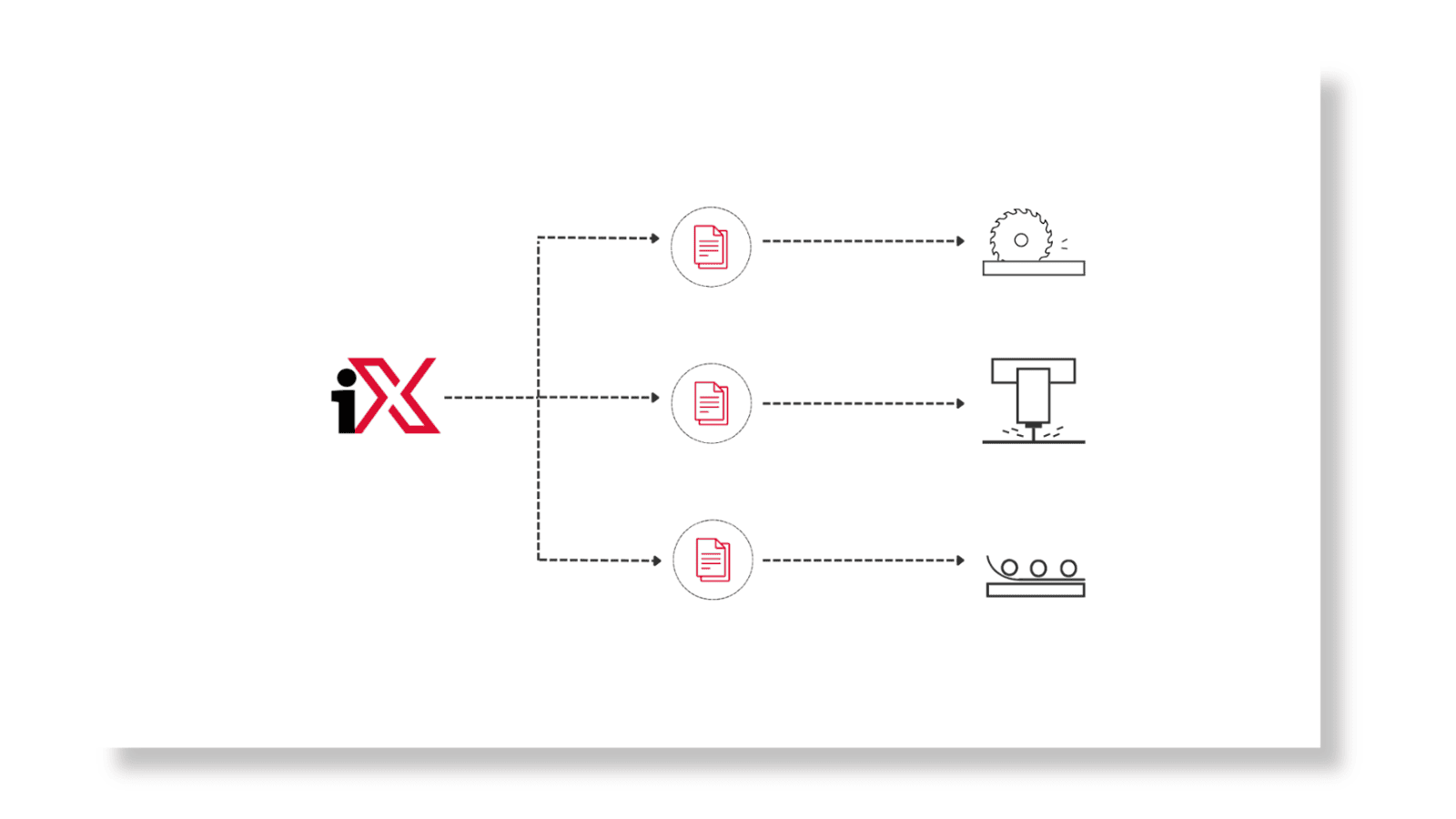

CNC Integration with Intelligent Manufacturing Data

- Object-Oriented approach.

- Automatically generates geometry data, technology parameters and process sequences.

- iX CAM Integration.

- Flexible Machine compatibility.

Comprehensive Machining Strategies & Optimization Techniques

- Converting traditional machining operations to automated NC programming.

- Define tool entry and exit paths to ensure smooth operations and prevent tool wear or collisions.

- Create mirrored toolpaths for machining symmetric parts, reducing programming time and enhancing consistency.

- Adjust machine coordinates for accurate positioning, correcting offsets for precise machining.

- Generate NC programs to machine both sides of a part, improving productivity with simultaneous or sequential processing.

- Design toolpaths to follow part contours, ensuring high precision and quality surface finishes.

- Assign the correct tools for each machining operation, optimizing tool changes to minimize downtime and improve efficiency.

Custom Cutting Optimization Interface

- iX CAM does not offer built-in cutting optimization but provides a configurable interface.

- Allows transfer of cutting dimensions, material designations, part designations and item numbers.

- Supports inclusion of component graphics and additional relevant information.

- Information can be output on component-specific labels for easy identification and tracking.

Barcode-Based Component Identification

- CNC production relies on clear workpiece identification through barcodes or similar methods.

- iX CAM allows the generation of unique part numbers based on customizable rules.

- Ensures each part can be easily assigned and tracked throughout the production process.

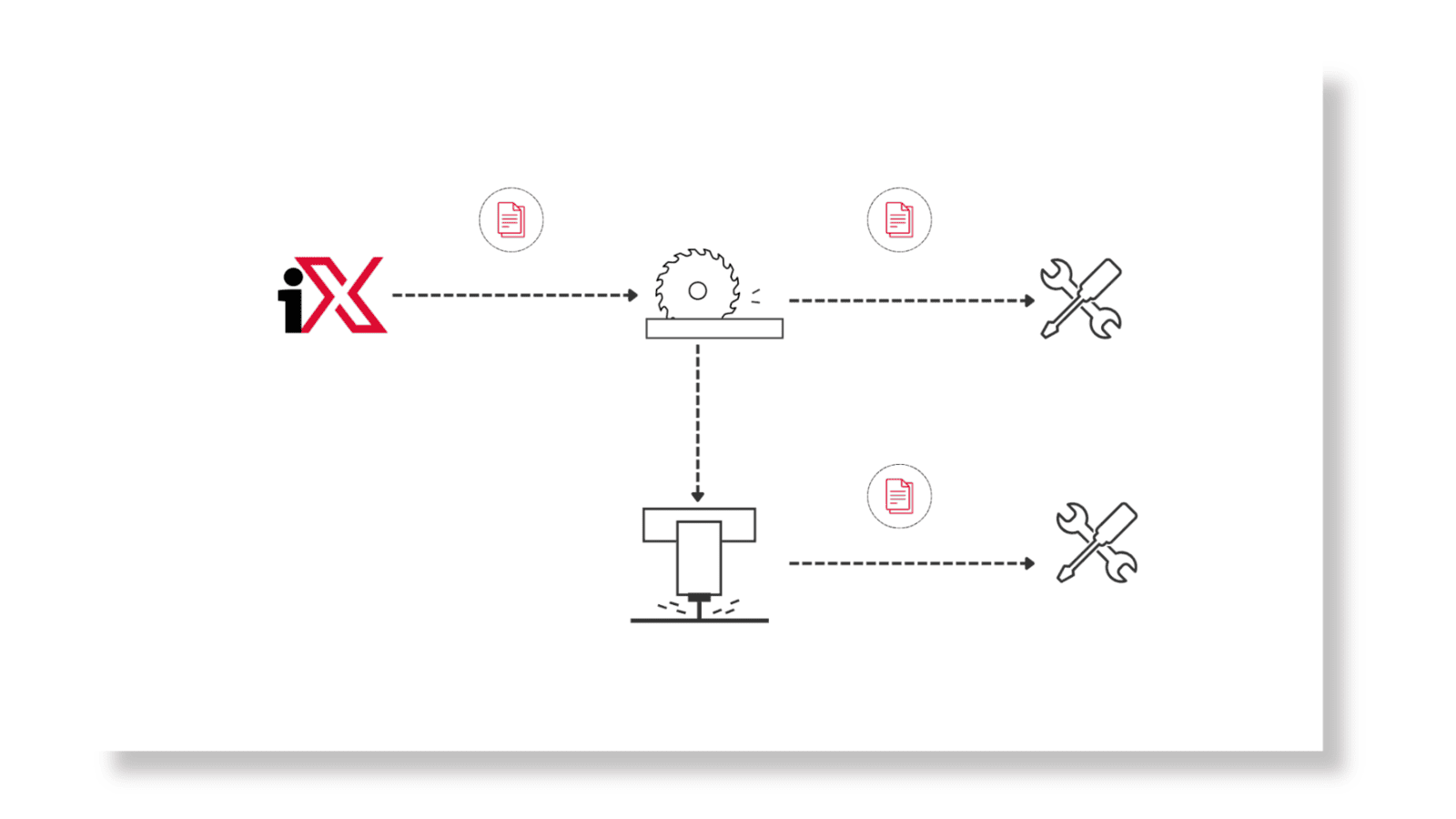

Nesting

Software offers a specialized module designed for seamless nesting operations. Currently, it supports advanced machines from Biesse and Homag, which combine nesting and CNC functionalities into a single powerful unit. Maximize productivity and precision with our cutting-edge technology tailored for these industry-leading machines.

Highlights

- Generates optimized cultists for efficient nesting operations

- Provides CNC programs for accurate machining processes

- Includes part assignment options with edge detailing capabilities

- Automatically optimizes board layouts with intelligent algorithms

- Offers a customizable nesting process with adjustable parameters and layout options

- Grouping parts for efficient grain part machining

Post Processor's

iX CAM sub-modules form a comprehensive package that unlocks the capability to generate machine-specific program files. Each machine requires a dedicated post processor to ensure precise output of machine-specific files.

Highlights

- Precision in generating machine program files

- Machine-specific, readable files

- Compatibility with various machine software versions and output generation

Support for 5-axis machines

- Distinctive output file naming

- Control of various machine parameters

- Management of tool information

Multi Workflow

The Multi Workflow feature enables the use of multiple CNC machines within a single workflow, allowing for different aggregate placements and postprocessors when needed.

Highlights

- "Process All Matching Workflows" function assigns parts to relevant workflows during the automatic CAM run, generating data to optimize machine utilization, especially during machine failures

- Easy sequencing of parts

- Automatic alignment of parts for each machine

- Generation of programs based on part segregation

- Automation of machine interlinking and scheduling

Sandwich

Part of iX CAM, this feature enables the generation of sandwich machining programs. With its specialized machine compatibility, IMOS stands out for its versatility and adaptability, offering seamless integration for various manufacturing needs.

Highlights

- Enables the generation of CNC programs for combined components that can be clamped simultaneously on one machine

- Specialized machine compatibility

- Versatile and adaptable for various manufacturing needs

Allows precise definition of which components are to be combined

Unique identification

Support for major brands

Edge

As a component of iX CAM, this feature allows IMOS to automatically create the program for premilling edges prior to edge banding, enhancing the workflow and introducing a semi-automated approach.

Highlights

- Reducing time by seamlessly utilizing input directly from imos designs

- Facilitating precise tool configuration for optimized performance

Enabling accurate edge number detection for efficient processing

Offering flexibility with custom machine configuration options